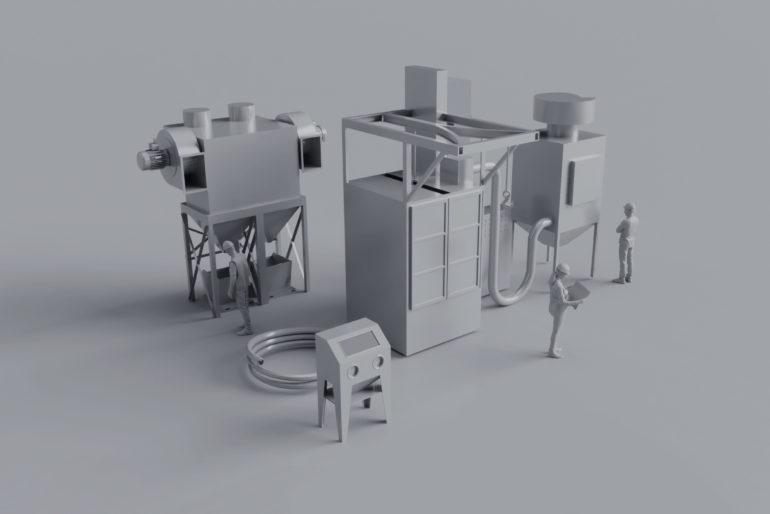

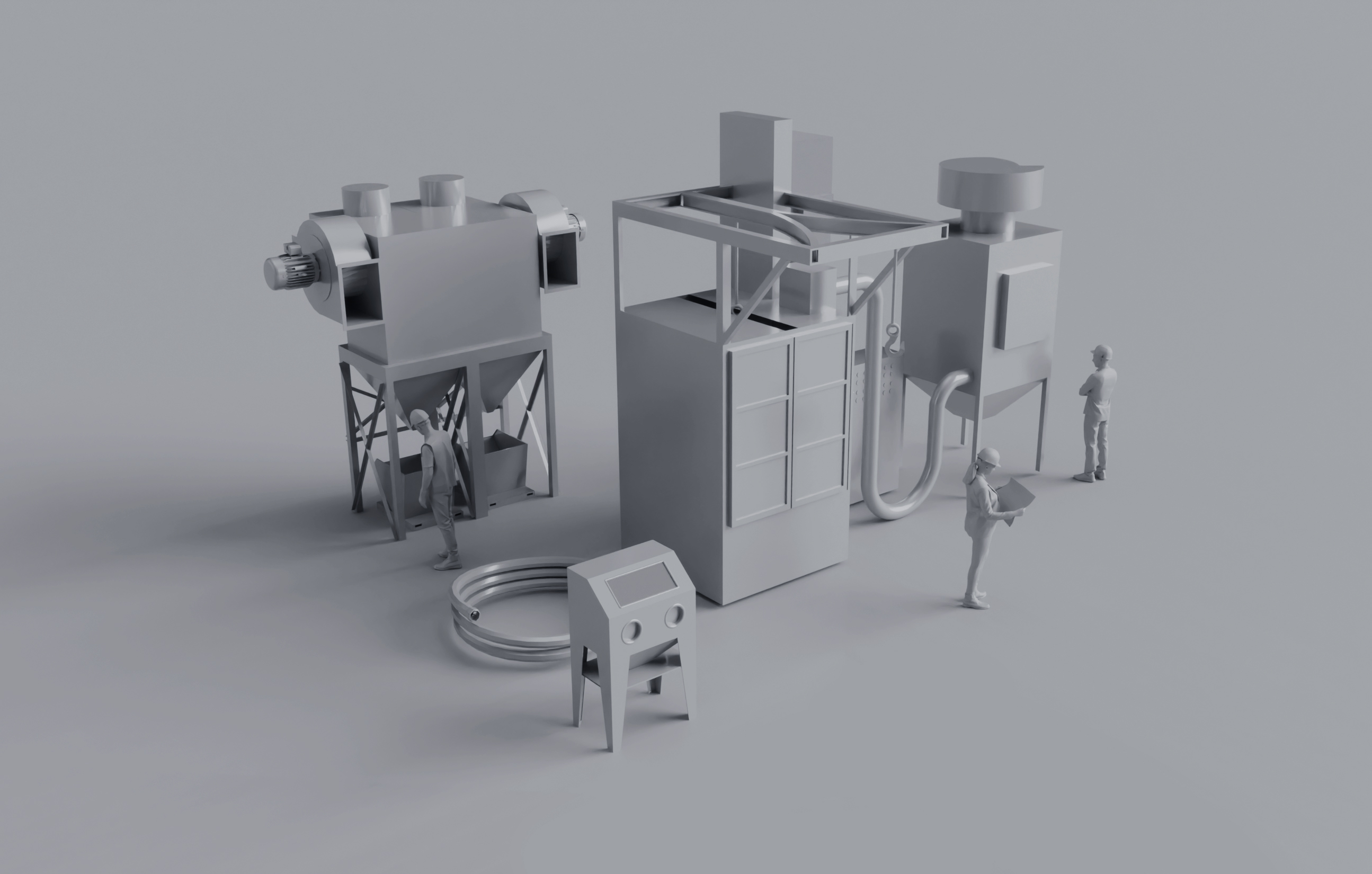

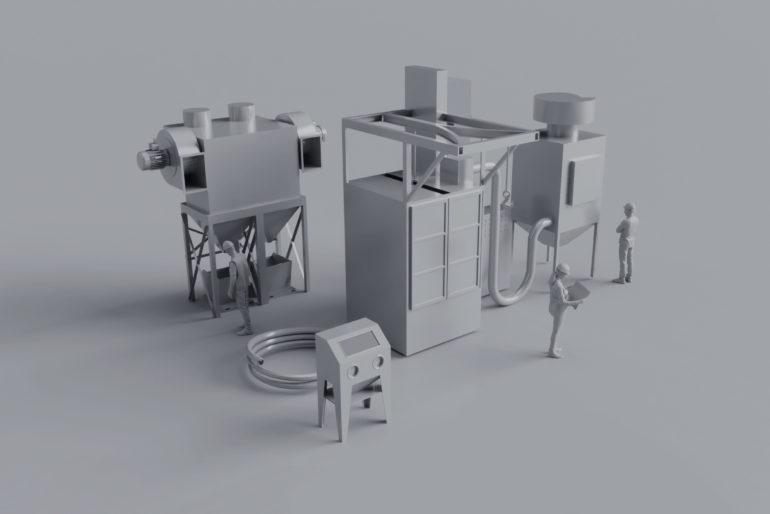

Blasting equipment

Automatic blasting equipment Recycling units Blast boilers SpongeJet blasting unitsAutomatic blasting equipment

They can be of the chamber or continuous type. The abrasive is thrown onto the part by means of the blast wheels, where it is subsequently conveyed to the elevator, separated from impurities and returned to the silo/abrasive hopper.

Recycling units

The units suck out the abrasive including blasted dirt. The abrasive is regenerated/recycled in the unit and the impurities are separated. The units are designed according to customer needs with different suction capacities and are able to recycle all commonly available abrasives.

Blast boilers

Depending on customer needs, we can supply pressure blasting boilers for blasting different types of abrasives. Pressure blasting boilers are equipped with a dosing valve and a remote control for starting abrasives.

SpongeJet blasting units

For blasting needs in areas where dust must be limited, we can supply a complete SpongeJet blasting unit for low dust blasting.